How to choose the right products?

Below, you will read more about how and why to choose the right products while considering the possibilities for reuse and recycling. After reading the texts, you have to answer the tasks listed at the bottom of the page.

When choosing bricks and mortar, it is important to ensure that the materials can withstand the exposure they are subjected to. Exposure refers to wind, weather, and usage, which the bricks must be able to withstand. By ensuring that the materials have the necessary properties, you avoid damage to masonry constructions.

Information about the properties of the materials can be found in their product data sheets or in the material's performance declaration. You can find the data sheets on the supplier's website.

Below is a table that describes the individual exposure classes:

|

Class

|

Microcondition for the masonry

|

Examples of masonry in this condition

|

|

MX1

|

In a dry environment

|

Interior masonry in buildings for general residential and office use, including the inner leaf of exterior cavity walls that are unlikely to become damp. Plastered masonry in external walls that are not exposed to moderate or heavy driving rain, and which are insulated against moisture from adjacent masonry or materials.

|

|

MX2

|

Exposed to moisture or water impact

|

|

|

MX2.1

|

Exposed to moisture, but not exposed to freeze/thaw cycles or external sources of significant levels of sulfates or aggressive chemicals

|

Interior masonry exposed to high levels of water vapor, for example, in a laundry. Exterior masonry that is shielded by roof overhangs or coping, and which is not exposed to heavy driving rain or frost. Masonry below the frost line in well-drained non-aggressive soil.

|

|

MX2.2

|

Exposed to heavy water impact, but not exposed to freeze/thaw cycles or external sources of significant levels of sulfates or aggressive chemicals.

|

Masonry that is not exposed to frost or aggressive chemicals, and which is located in external walls with coverings or aligned roof overhangs, in parapets, in freestanding walls, in the ground, under water.

|

|

MX3

|

Exposed to water impact + freeze/thaw cycles

|

|

|

MX3.1

|

Exposed to moisture or water impact and freeze/thaw cycles, but not exposed to external sources of significant levels of sulfates or aggressive chemicals.

|

Masonry like class MX2.1 exposed to freeze/thaw cycles.

|

|

MX3.2

|

Exposed to heavy water impact and freeze/thaw cycles, but not exposed to external sources of significant levels of sulfates or aggressive chemicals.

|

Masonry like class MX2.2 exposed to freeze/thaw cycles.

|

|

MX4

(supplementary class)

|

Exposed to salt-saturated air, seawater, or de-icing salt

|

Masonry in coastal areas. Masonry in the immediate vicinity of roads

that are salted in the winter.

|

|

MX5

(supplementary class)

|

In an aggressive chemical environment

|

Masonry that is in contact with soil or fill soil or groundwater where moisture and significant levels of sulfates are present. Masonry that is in contact with very acidic soil, contaminated soil, or groundwater. Masonry near industrial areas where aggressive chemicals are carried through the air.

|

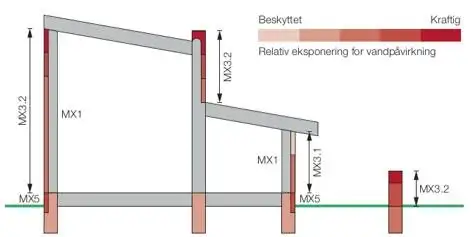

Sketch with examples of exposure classes: